Estoban Corporation - We all work hard making the best commercial chimney scanning equipment!

Our history as told by Jim Gillam in an article for SNEWS in 2000.

To read this in a full-page format, click here. Tom & Esther Urban: Chimney Scanning Innovators

By Jim Gillam, Photos by Harriet Gillam The Chim-Scan factory, headquarters of the fertile minds of chimney scanning pioneers Tom and Esther Urban, is located amid fertile rolling hills rich with corn and soybeans near Fairfield, Iowa. Looking like anybody's garage, you'd never know that a specialized and complex video documentation system for flue inspection is being crafted inside.  Tom, Shelley, & Esther Urban Tom, Shelley, & Esther Urban

With their single full-time employee, Marvin Fitzsimmons, building the cameras, and Tom and Esther doing everything else, including parts ordering, machining, welding, wiring, woodworking, marketing and order taking, it's a true Mom & Pop operation. Tom and Esther are a lively, industrious couple, cooperating at home and in business and finishing each other's sentences!

In addition to the business enterprise, Tom and Esther are home schooling their thirteen year-old daughter, Shelley. Quite a few in the chimney industry have watched Shelley grow up as she often accompanies her parents to conventions and workshops. What is a Chim-Scan®?

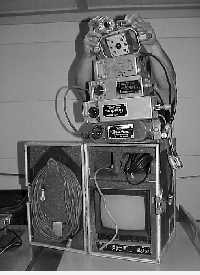

Chim-Scan is a registered trademark for the vision product of the Urbans' corporate entity, Estoban Corporation. It is a remote imaging apparatus, designed to be raised or lowered into a chimney. Its purpose is to provide the viewer the ability to see the interior portions of the chimney up close, and to provide a view of areas that cannot be seen by regular visual means. Other applications include air ducts, crawl space areas and other confined spaces, and search & rescue. Chim-Scans are available in several different configurations including remote focus or auto-focus, black and white or color, a 12-volt power option and with a choice of one, two or no VCRs and/or a digital recorder on board. In addition to the Chim-Scan itself, Estoban Corporation manufactures accessories and related products such as Kwik-Lock rods, robotic cameras for air duct work, and remote controlled carts for scanning in inaccessible areas. Each Chim-Scan system is built from scratch using commercial grade and hand crafted components. Because the systems are a limited production specialty item for use in the chimney maintenance trade, parts are unique and many of them are made right there. A rack near one wall holds bars of aluminum and grey PVC. "Our front plates are actually cut from solid aluminum," Tom says. "Then we drill it down and polish it before putting the lights in. The mechanisms and focusing, this is all done out of solid stock," he adds. "It has to be cut, machined off, finished, then the lens gets put on." In order to accomplish this, they've accumulated an array of special tools. Esther says, "We have a wood shop for building the cases, a metal shop for many of our components..." "...And an electronics shop for wiring," adds Tom. "Esther does a lot of the cable wiring." And how did they learn to do all this? "I have a degree in dairy science," replies Tom, "but I have done some night courses in electronics and machining technology. Thank God, He gave me a gift that I can work with my hands." The Vision Tom and Esther met on a dairy farm in 1975 and were married in 1976 after Tom graduated from college. After a stint with the Peace Corps in Swaziland in 1977-1978, Tom and Esther started Urbans' Chimney Sweep and Supply in northeast Pennsylvania in January 1979. They learned everything they could about chimneys. Tom took courses on oil burner combustion and heat loss evaluation. They joined the National Chimney Sweep Guild (NCSG) in 1980. Every day, they encountered a lot of glazed creosote. "Everybody bought black boxes and installed them in houses with outside masonry chimneys, built by their friends," Tom recalls. Quickly realizing that attempting to vent relatively low temperature, particulate laden gases up cold, oversized chimneys created excessive deposits of creosote, the Urbans searched for a source of chimney liner pipe and began relining. "There wasn't anything commercially available yet for chimney sweeps," notes Esther. "We had to go to Chicago to buy liner!" From the Chicago manufacturer, Tom learned of the concept of wrapping a liner with ceramic blanket, although it was not being used for chimney liner applications. "I actually brought the concept of wrapping stainless liner with ceramic blanket to our industry," Tom states proudly. Along the way, they got involved with an insurance adjuster with a masonry background. Tom occasionally accompanied the adjuster as he made his rounds. Together they began to see the need for a better way to observe the interior of chimneys. Tom went to the National Chimney Sweep Guild convention in 1983 and talked to other sweeps about his concerns. "They were saying they could look down a chimney and see everything," Tom recalls incredulously. "I'm thinking, 'I've got 20-20 vision, but I know I'm missing things! Coming out of that convention, crossing the bridge out of St. Louis, I vowed that before the next convention I would have a camera system!" When they returned home, Tom told the adjuster about his idea of finding a camera that could be used inside of chimneys. "Call me when you get it," the adjuster said. Thus encouraged, Tom began looking for sources of equipment. Eventually he found himself at a security convention in New York City. "It was huge," Tom remembers. "I talked with the security people about my idea. They said, 'You want to do WHAT with that camera!?'" Development Tom did find one fellow who was interested in his idea. Tom emphasized that he wanted a camera that could be remotely focused to provide clear imagery. After about four months of development, they came up with a camera system with a 9" monitor packaged in a footlocker on wheels. At the 1984 NCSG convention in Washington, DC, Tom introduced video scanning to the industry. His invention was described as "the show stopper of the convention -- Hi-tech meets chimneys!" and he was interviewed by CNN. Initial orders proved disappointing. "So we just used it in our business," Esther recalls. They offered their scanning services to insurance companies and began to do chimney fire damage investigations for them. Eventually word about the Chim-Scan began to get around and orders started coming in. Tom began to spend increasing amounts of time with Fred Schukal of Sleepy Hollow Chimney Supply and Bill Paynton of Improved Consumer Products at various chimney industry workshops and conventions, providing relining instruction and promoting the idea of chimney scanning. At home, Esther managed the service business. "People knew us," she says. "They were almost all repeat customers at that point. I'd call them and ask if somebody could put the big ladder up. Otherwise they had to wait until Tom came back. I swept a couple a day while he was gone. "But after the second time around of just Esther coming, it was like, 'Well, where's Tom? Is he too busy to see us?' Actually, he was!" Tom and Esther decided to focus on the Chim-Scan business and sold their service company. "One door was closing and another was opening," reflects Tom. "I was talking to Bob Daniels [of Copperfield Chimney Supply in Fairfield, Iowa] about distributing our product when the topic came up about a new position with his company, a technical advisor. Bob asked, "Do you want the job?" "After working out some details, we moved to Iowa." Tom assumed the new position at Copperfield of Director of Technical Advisory Services in July 1985. His duties included answering sweeps' technical questions and running the technical day of Sooty Bob's seminars. Copperfield distributed the Chim-Scan. Meanwhile, the manufacturing of Chim-Scans remained with an employee in Pennsylvania. "We started getting phone calls that told us something was not right," Tom remembers. Tom decided to leave Copperfield and bring the Chim-Scan manufacturing to Iowa. Esther jokes, "I offered him better fringe benefits. But not much pay!" Built to Last "The way the cameras are designed and built, you've got to be a beast to break them," Tom brags. Last year they had an opportunity to refurbish the third camera they made. It has seen three owners. Today's systems are color but "if they want to stay black and white and the monitor is still good, we can just put a new camera in them," Esther says. Not that they recommend it, but Tom claims, "They are designed to withstand a fall out of the back of somebody's van."  Chim-Scan® cameras through the ages. The earliest models are on the bottom. More recent models at the top are rounded, much smaller and view color. Chim-Scan® cameras through the ages. The earliest models are on the bottom. More recent models at the top are rounded, much smaller and view color.

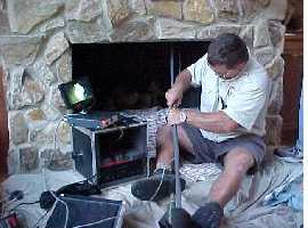

Changing Technology

Tom says it's a constant challenge to keep up with the changes in electronics and the shifting availability of products in today's market while trying to keep the price of the Chim-Scan stable. "When you look at the advancements that have been made, it's just phenomenal," Tom marvels. While technology continues to change rapidly and they want to take advantage of advancements, they also want to continue to market a product that will last and not become obsolete. Baby Monitors Tom has some problems with the "baby monitors" being marketed to chimney sweeps. "The idea of showing a customer something without documentation is a huge step back for the industry," Tom contends. "When the sweep has shown the client the problem on the monitor, is he/she then going to write all that information down? There is a big gap there! "I think a $400 camcorder can do nearly the same thing, plus tape it for your notes for estimates. Or use a digital camera." Serving the Industry Tom, along with Jerry Isenhour and Ken Robinson, is one of the chimney and venting maintenance industry's leading proponents of documentation, and they have presented several "Diagnosis & Documentation" seminars around the country in recent years [see SNEWS - The Chimney Sweep News, March/April 1999, page 10]. Blume, The Merry Sweep of Greenville, SC, prepares to scan a chimney at the first known 30-person Level 3 Inspection during the South Carolina Guild's Connemara retreat in August 2000. Photo by Ron Brigman.  Blume, The Merry Sweep of Greenville, SC, prepares to scan a chimney with a Chim-Scan® Camera at the first known 30-person Level 3 Inspection during the South Carolina Guild's Connemara retreat in August 2000. Photo by Ron Brigman Blume, The Merry Sweep of Greenville, SC, prepares to scan a chimney with a Chim-Scan® Camera at the first known 30-person Level 3 Inspection during the South Carolina Guild's Connemara retreat in August 2000. Photo by Ron Brigman

Since his first presentation for the National Guild in 1984, Tom has appeared before hundreds of sweep and hearth industry groups. He's spoken on various topics, including relining techniques, oil burner servicing, and inspection practices.

He served on the NCSG Technical Committee from 1985-1999 and was its Chair in 1997 while serving a three-year term on the Board of Directors of the NCSG and Chimney Safety Institute of America (CSIA). Tom and Esther were founding members of the Pennsylvania Guild in 1985. In November and December 1999 he worked with the producers of ABC News' 20/20 show on a segment about carbon monoxide poisoning that was aired in January 2000 [SNEWS - The Chimney Sweep News, March 2000, page 14]. And in August he flew to Boston to provide vision equipment for an episode of This Old House. "We really want sweeps to be the best they can be, using this equipment," Esther emphasizes. "And we work at it really hard!" Contact Tom, Esther and Shelley Urban of Chim-Scan at 641-472-7643.

|

Thomas and Esther Urban Thomas and Esther Urban

Shelley Urban Shelley Urban

Marvin doing repairs Marvin doing repairs

Marvin has been at Estoban Corporation for over 30yrs.

He mainly does repairs and production. If your Chim-Scan is 20 years old or older, then Marvin's repaired it, and if it is 25+ years old or older, he probably helped build it. He also drives School Bus for the local school district. Marvin has never met a lawnmower that he didn't like!! :-)  Alicia working on wiring Alicia working on wiring

Alicia worked at the oldest printing company in Iowa until it closed. She gained her chimney knowledge working at a local distributor in customer service and order taking for almost 20 years. She is currently the third voice you may get when you call us. Alicia is in charge of the wiring department and helps with repairs.

Ray at a trade show. Ray at a trade show.

Ray joined us 9 years ago after running his own moving business for which he owned for over 10 years.

Ray is in charge of the shipping and receiving department, and he is also QC for all new units and repair. Ray is also the Urban family GPS Locator. He can always find Tom, Esther or Shelley.

Karen Formen started in the hearth industry over thirty years ago. Her first job was in Copperfield's Technical department, starting in 1985. She returned to Copperfield after working for a different chimney supplier as Director of Marketing. She's spent her years mostly in technical, and product development gaining knowledge and experience. She has held positions such as Merchant Analyst, Sales, and Technical Sales at Copperfield/Home Depot. She's a published author, you can get her book Design Ideas for Fireplaces on Amazon.

Terese - The Cable Girl Terese - The Cable Girl

Terese is a retired naturalist who became our part-time Cable Girl.

On left is Solomon, the guard dog and good listener. On back right is Bella, the resident party animal where every day is a good day, even Monday. In front is Max the cat. He is also known as Inspector 12. On left is Solomon, the guard dog and good listener. On back right is Bella, the resident party animal where every day is a good day, even Monday. In front is Max the cat. He is also known as Inspector 12.

Our Office Perks - the Furry Employees whose main job is stress reduction and picking up scraps. They are great at in-person customer service and are also our fierce security team. Solomon, the larger of the two is a golden doodle and is Shelley's bring to work buddy who is also known as the therapist for everyone. Bella, the other dog is a terror - a soft-coated Wheaton Terrier and is the resident party animal. She is small, but mighty and she is that annoying always happy employee in the office. Maximus is the longest furry employee at 13 years old. He arrived doing QC on a UPS Truck and has never left. He was the official QC until Ray came. He is since retired and is now the resident motor therapy and French fry thief. For those worrying about animals in the workplace, the above job titles for the humans are really just their part time jobs since their full-time job is just letting the cat and dogs in and out. |

The reality is that Chim-Scan® is a smaller family-owned business. The reality is that Chim-Scan® is a smaller family-owned business.

The Chim-Scan® Story

40 years of innovation in Chimney Scanning Featured in Blue Collar Magazine, April 2021 To read this in a full-page format, click here. Twenty years ago, Jim Gillam of SNEWs wrote a great article about Estoban Corporation and Chim-Scan®. Now it is time to bring you up to date in 2021. Many assume that Estoban's location is in some big glass building with a giant loading dock. This mental image could not be farther from the truth; 99.5% of people driving by Estoban don't even know they are there. Estoban is located outside a small town called Fairfield in the southeast corner of Iowa. If you google Fairfield, Iowa, you'll get some fun articles, videos, and even an Oprah visit. Estoban isn't a spelling error; it's the combination of Owners' names. E stands for Esther, S stands for Shelley, TO stands for Tom, and BAN stands for Urban. Mom and Pop, who revolutionized the industry, still run the business. Jim's article is a great way to know how Estoban started. So, here's a QR code to Jim's article; please read it.

In a brief overview: Tom and Esther started like many in the late '70s as Chimney Sweeps; as time went on, Tom's curiosity and concern for his customers' homes got the better of him. Like all sweeps, customers asked him, 'Is it safe?' and He couldn't wholeheartedly answer because he knew he didn't see everything.

Tom started tinkering. He traveled to Cornell University to search the library's optics section of Thomas Registers. A year later, Tom built the Footlocker Camera, lovingly named was the size of a footlocker with a lens. In 1984 at the NCSG convention in Washington DC – Chim-Scan® was shown for the 1st time to a national audience. It was pronounced a showstopper by CNN News Channel, and many thought Tom was nuts for sticking a camera in a chimney, but time has shown he's an innovator.

So, in the early 2000s, Chim-Scan® built units that connect to computers, which was AWESOME. Then the World experienced the 'wonderful' (please note sarcasm) jump in Windows Operating systems of XP>Vista>Windows 7>Windows 8> and finally 10. During this jump, they learned the hard way of working with 3rd party parts and programs: one day, they are here, and the next, they're gone.This great inconvenience led them to look for other recording abilities. They have used Polaroid, VHS, Floppy disks, CF burners, PDAs, Computers, DVD recorders, and four versions of SD recorders - all done by 2010.

Estoban stays current on new technology, but with the rise of disposable technology, they have become even pickier about what they put in their equipment. They only buy and work with commercial electronics, and commercial electronics tend to move slightly slower than consumer electronics. They use Commercial because it has to work, day after day, with the option of repairing. Shelley explained, "One would never trust a sewer company if they showed up with a teeny tiny camera hooked up to their phone. That stuff is cool and cheap, but it is unable to stand up to everyday abuse."  The Chim-Scan® lab is located in Fairfield Iowa where we have hosted several training classes and online chimney inspection videos using our Chim-Scan® cameras and other chimney inspection cameras as requested. The Chim-Scan® lab is located in Fairfield Iowa where we have hosted several training classes and online chimney inspection videos using our Chim-Scan® cameras and other chimney inspection cameras as requested.

Backing up to 2000, when Jim's article came out, Estoban had just added on the schoolroom (where Shelley homeschooled until high school), a new big office, and the machine room. A total of about 2,000sq ft: they quickly outgrew that by 2008, they added on Electron row, which now serves as a hallway, and the 'shipping room,' which is now the office, added another 800sq ft. The schoolroom transformed into Marvin's repair Room, Bathroom, and Commissary. For anyone wondering, Marvin is their oldest employee; he's worked for Estoban for 30 years, hence why he gets his room. The original shop was now surrounded and became half wiring, half internal highway.

In 2014, they had a record year but at a dreadful cost. From July to January 2015, the entire company worked seven days a week, sometimes 12 hours a day. This busy schedule was due to disappointing results from high expectations of a cheaper product that came on the market that did not fulfill the vision needs that a Chim-Scan® can produce. Well, that opened a fantastic door. They heard from people they hadn't spoken to since the mid-'90s, and many jumped on the 'I want to upgrade my old unit' bandwagon.

For those who might not know, Estoban builds Chim-Scan® Units right in the Heartland and repairs and upgrades units built since 2010. It used to be 1995; however, they had to change to 2010 as new and old technology is a little over 66 units a month, which may sound small, but that number does not include routine repairs or new units, which always work well together. They were housing units in Tom and Esther's front/living room before the busy season repairs came in mid-September. They realized during this time that they needed to expand. As of December 31, they had upgraded over 400 units. When you do that, math bumps the unit number around 800.Eight hundred may seem like a medium-sized number, but to put it into perspective, they don't physically build the monitor, SD recorder, and camera chip. Everything else is built in-house.

When you look at a Chim-Scan®, you are looking at a controller that Alicia or Shelley wired, a Case that Tom or other staff built, a reeler that Esther or Therese wired, and a camera that Tom or another employee built. Plus, Alcia and Shelley are small component assemblers who help keep the rest going. In 2016 the new addition or Backroom was added on; They had a great local team come, and the whole building was constructed, insulated, concrete poured in 4 days. It was amazing. The Urban Family spent the next two weeks riding bicycles around the 4,000 sq ft addition, waiting for the concrete to cure.

The new addition starts with a 9 ft ceiling and then jumps to a 16 ft ceiling, allowing us to build a mezzanine. The Back half of the 'Backroom' is Tom's Chimney Lab. They have a masonry fireplace, prefab insert, and a masonry thimble chimney; the mezzanine allows roof access to these chimneys just by climbing a set of stairs. Watching their videos, you'll see the Lab; they use it daily to test repairs, new units, and new products. There is also a 14x30 classroom that provides space for training, zoom meetings, and video presentations. When it's not a classroom, it is the 3D printers' home. They use three printers to print the stabilizers for the cameras, which frees up the CNC machines. Tom's favorite tools are his four CNC machines; they have sped up production 100-fold. Parts are constructed in-house for the Chim-Scan®. Tom, shares these tasks with other employees. In 2020, Estoban was able to stay up and running even when other businesses had to close. s stated before, Estoban also repairs the equipment it builds; this involves the oldest employee Marvin, and Ray, the shipping and receiving guy. Every package that comes in gets unpacked and photographed by Ray, who then cleans it within an inch of its life and hands it over to Marvin, who does 80% of the repairs and upgrades. Esther, Alicia, Billy, and Tom pick up the other 10%. Once a Repair or Upgrade is complete, it gets reviewed, tested, and tested again by Ray or whoever is free. It is then cleaned again (as fine soot is worse than glitter to get rid of), photographed, boxed up, and shipped out.

Once new units are complete, they 'sit' for 8 hours, being turned on and off, running for a few minutes to hours, are taken to the Lab, and run up the chimneys to test every part of the unit. They are then photographed, packed, and shipped. You may ask, "What's with all the pictures?" Well, it serves many purposes. The primary purpose is that we can see what they're talking about when a customer calls. Some may ask, with listed jobs above, who answers the phone? Shelley and Esther are the voices of Estoban; they cover customer service, sales, and tech support. Shelley is also a webmaster and marketing department.

Estoban also has the benefit of being a pet-friendly workplace. If you stop by for a visit, you receive a greeting by the booming voice of Solomon the Golden Doodle, the little booming voice of Bella the Wheaten terrier, and the dismissive glance of Max, the cat, aka Inspector 12. Solomon and Bella oversee internal security, employee well-being, and occasional photo shoots. Max oversees everyone's work, sending random emails (touch screen computers) and the rare photoshoot.

Speaking of the past, you may ask, What about the future? Shelley plans to run Estoban if Tom and Esther ever retire; she hopes to maintain their standard of excellence and keep growing with technology. Tom, teaching a class in scanning chimneys and inspections Iowa in our Lab. Check out Tom’s technical blogs and videos by clicking on these words.

|